Want to know more about this article?

Plastic recycler Uppact builds new ‘UnWaste Factory’ in Delfzijl

Uppact scales up with support from NOM, the Groningen Growth Fund, and Polestar Capital Circular Debt Fund

Processing 4,000 tons of plastic waste annually into valuable construction materials—that’s the ambitious goal of Uppact | The UnWaste Company, now that funding for the entire project has been secured. The NOM and Groningen Growth Fund (GGF) have joined as shareholders, while the Polestar Capital Circular Debt Fund has provided a loan. Together with an earlier JTF subsidy, this financing enables Uppact to launch the first production line at its DEMO factory in Farmsum by mid-next year.

This factory will play a pivotal role in the transition to a circular economy, where waste streams are recycled and repurposed into useful, preferably circularly designed, products for the regional market.

The scale-up, led by Jan Jaap Folmer and Michel Walstock, has developed an innovative capability: processing unwashed, unsorted, and unshredded streams of mixed plastic and textile waste into durable posts, planks, and beams. This is made possible by the Unwastor, a machine developed by Plastech Recycling in Australia, already demonstrated at maritime waste collector Bek & Verburg’s facility in Eemshaven.

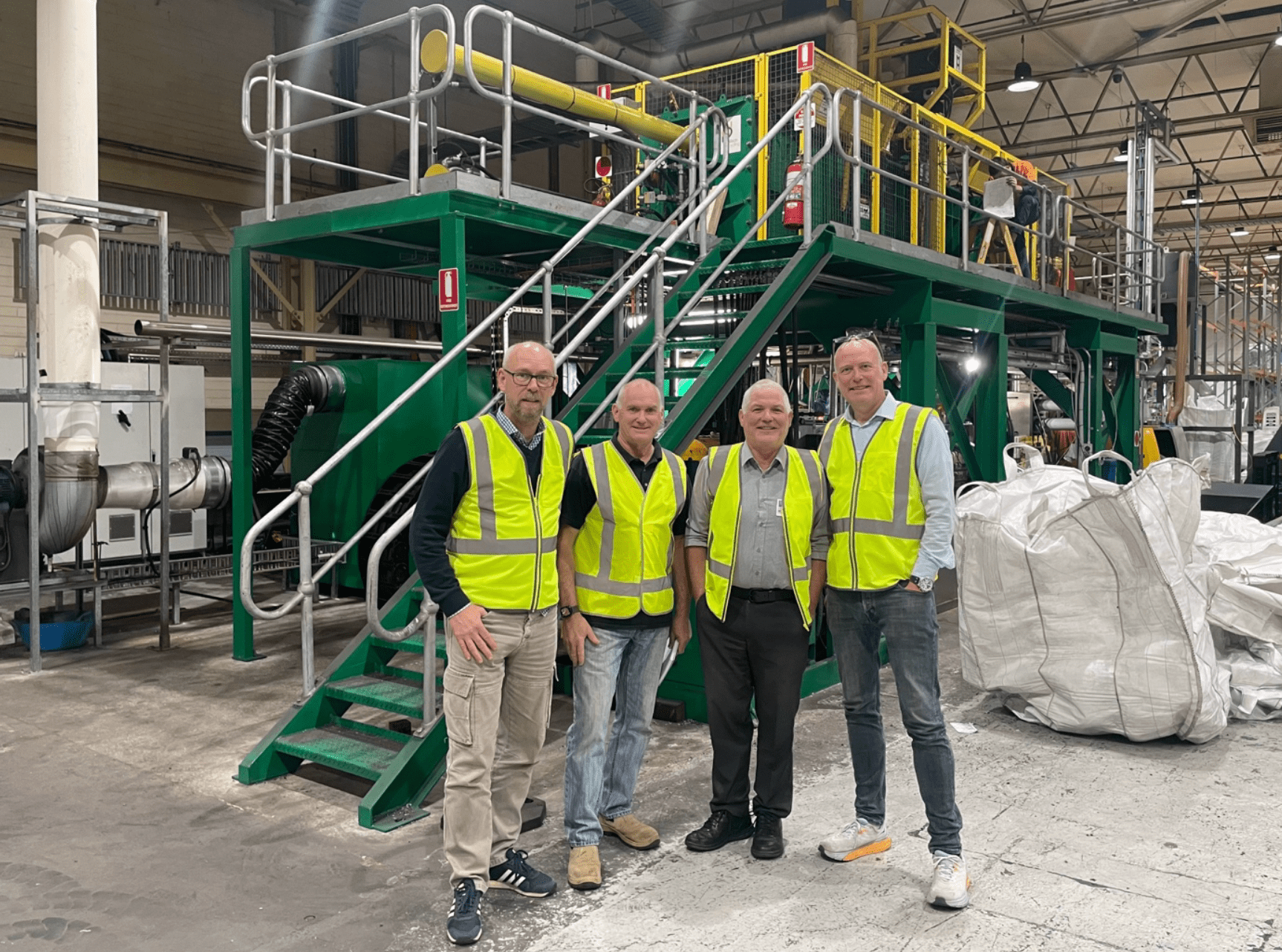

Michel Walstock (l) and Jan Jaap Folmer (r) last week in Melbourne (Australia) with Plastech colleagues Peter and Colin Barker in the middle.

Now, it’s time for the next step—a full production line at the Chemport Innovation Center (CIC) in Farmsum. With financing secured, Folmer and Walstock recently traveled to Australia to inspect the Plastech Mixer-Melter before its preparation for shipment to the Netherlands.

“This is a crucial moment. Securing funding for a project like this is a major challenge, so we’re thrilled by the confidence shown by NOM, GGF, and Polestar Capital to make our DEMO factory a reality,” said Michel Walstock, CFO of Uppact. “Now we can move forward, creating as much impact as possible. That’s what this is all about—keeping plastic out of incinerators,” added Jan Jaap Folmer, CEO of Uppact.

The Unwastor in the DEMO factory will be over three times the size of the test model currently operating in Eemshaven. Simply put, the machine processes all types of plastic waste and outputs high-quality products—posts, planks, and beams for construction, as well as fenders for the port of Delfzijl. “Our customers are ecstatic about the quality of our products,” said Folmer.

The past few years have proven that Uppact’s vision is achievable

Making an impact

Emma Schakel, investment manager at the Groningen Growth Fund, remarked, “Uppact aligns seamlessly with our objectives. We aim to strengthen the region’s green chemistry sector, and that’s precisely what Uppact can achieve—recycling and turning it into a profitable model, creating maximum impact.”

The NOM is also eager to contribute, according to its investment manager, Sytze Hellinga: “We see the potential not just in the process but also in the team. The past few years have proven that Uppact’s vision is achievable. We look forward to working together to create an impactful future.”

Jan-Willem König, CEO of Polestar Capital, highlighted the complementary nature of Uppact’s technology: “The ability to process plastic waste that mechanical recyclers reject makes this technology a valuable addition to existing recycling methods. Uppact contributes to greater circularity in the plastics chain—a shared goal for both Uppact and Polestar. We’re delighted that our loan can help make this possible.”

“We’re excited to take this significant step toward a sustainable future,” added Folmer. “With the support of these investors and partners, we look forward to building a circular future.”

About Uppact

Uppact | The UnWaste Company expects its first DEMO factory to extract 4,000 tons of plastic and textile waste from the waste stream annually, preventing incineration. This reduces dependence on primary raw materials and lowers CO2 emissions. Uppact plans to scale further in the Northern Netherlands and establish multiple similar facilities across the Netherlands and Northwest Europe. This approach aligns perfectly with Dutch and European policies aimed at promoting a circular economy by recycling and reusing as much plastic waste as possible.

About PCDF

The Polestar Capital Circular Debt Fund (PCDF) is Europe’s largest debt fund dedicated to financing the transition to a circular economy. Recently closing at €240 million, PCDF invests in innovative circular projects with the potential to create systemic ecological impact globally, whether by reducing waste, recycling, or replacing fossil-based raw materials. These projects often face challenges in securing financing due to their innovative nature and capital intensity. By bridging this funding gap, PCDF enables circular production companies to scale their technologies and business models commercially, paving the way for further financing from other investors. PCDF investments benefit from EU support under the InvestEU program.

About NOM

NOM is the investment and development agency for the Northern Netherlands, offering tailored financing and advice to innovative entrepreneurs seeking to grow or establish themselves in the region. NOM supports entrepreneurs with funding, connections, and knowledge, fostering sustainable economic growth in Northern Netherlands.

About Groningen Growth Fund

The Groningen Growth Fund is the flagship fund of the Economic Board Groningen and the Province of Groningen, driving economic growth and job creation in the region. It aims to boost business activity and employment in Northern Groningen, making a lasting impact.