‘Thinking in circular flows’ – CCU

The chemical sector needs to go green, and a lot of hard work is being done to achieve this. Like, for example, converting carbon dioxide (CO₂) into usable chemical compounds, reducing greenhouse gas emissions and replacing the use of fossil fuels as raw materials for all kinds of products. Delfzijl aims to become the world's first CO₂-neutral chemical cluster.

Original article published by NoordZ

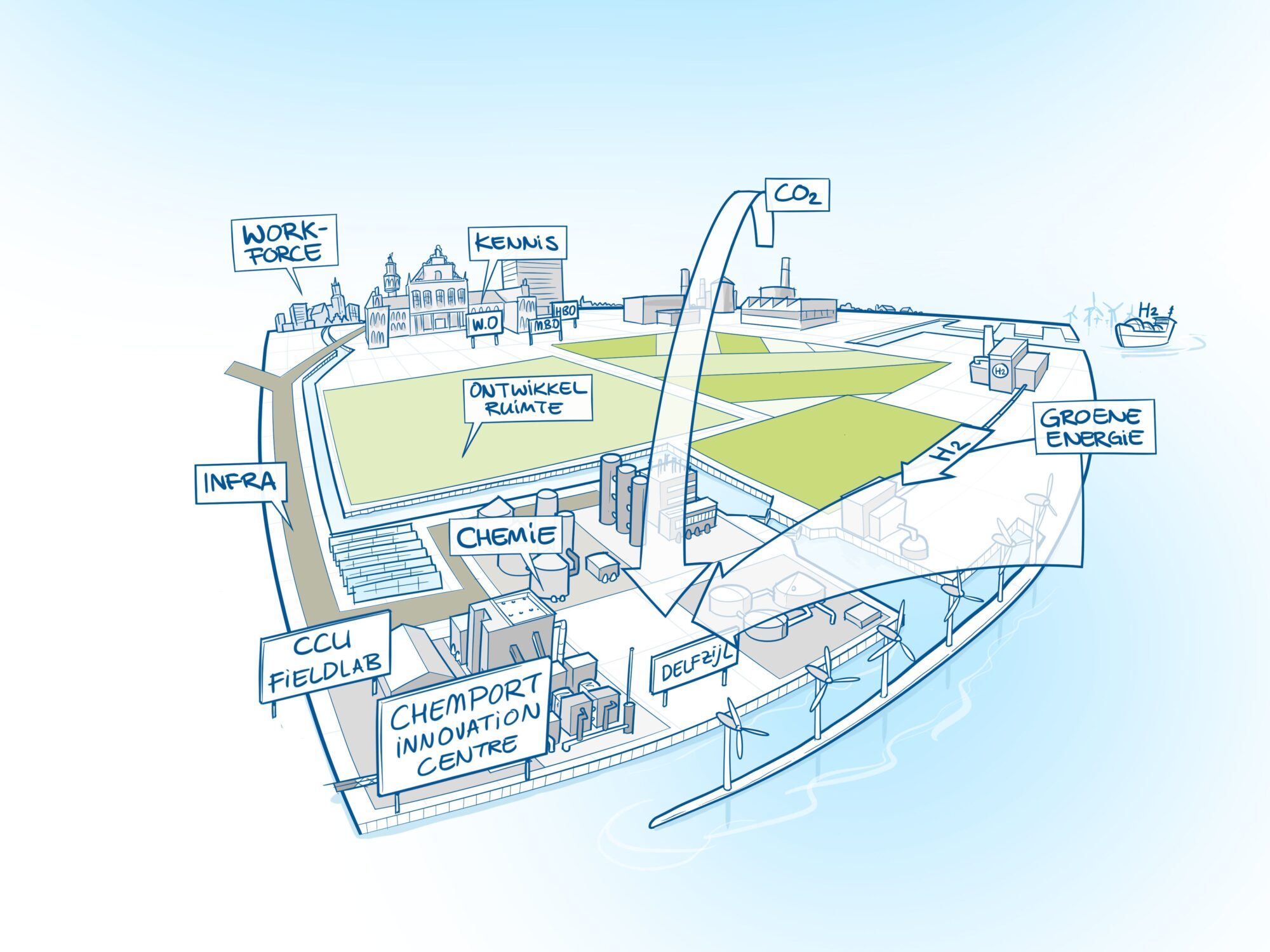

Several companies, knowledge institutions and governments in the province of Groningen are working on this. Chemiepark Delfzijl appears to be an excellent location to test this new technique, also known as CCU (Carbon Capture and Utilisation). Who knows, the world might soon be running on CCU technology from Groningen.

Professor of Biochemistry at the University of Groningen Matthias Heinemann, who is also one of the initiators of the FutureCarbonNL growth fund proposal, is enthusiastic: ‘Besides ASML, this could be the next showpiece to help the Netherlands climb up the technology ladder. If we don’t, we will soon be overtaken left and right and become increasingly dependent on other countries.’

Carbon transition

Maaike van Heeren, working at Chemport Europe, explains what the carbon transition entails. ‘Almost all products we use every day contain carbon atoms, think toothpaste, clothing, packaging materials. Over 90 per cent of all products are made from fossil sources. We want to get rid of that, because it puts too much CO₂ into our atmosphere, which is bad for the climate. Carbon transition means making products with renewable carbon sources. So, that we move away from fossil sources. With CCU (Carbon Capture and Utilisation), we capture CO₂ and reuse it as feedstock. This can be done through chemical conversion, biological processes and mineral carbonation.’ CO₂ capture happens, among other things, at waste-to-energy plant EEW (Energy from Waste B.V.) in Farmsum, about which site director Wilfred de Jager tells more later in this article. ‘A lot of things are already happening in this field in the northern Netherlands,’ Van Heeren continues. ‘Under the flag of Chemport Europe, we are bringing companies, knowledge institutes and governments together, enabling the transition to be accelerated. This is happening in the areas of technology, finance and permits. Clearly, all the ingredients to make it a success are here.’

The Chemport Innovation Centre is the spider in the web. It is the place where companies can further test the technology from the laboratory on a larger scale. ‘Where possible, we link the projects with existing or new companies. There is still a long way to go, but there is no doubt that the Northern Netherlands is pioneering the carbon transition, which will eventually allow green raw materials to be used for the production of chemical products.’

Capturing CO₂

EEW is one of the companies that has been working on the raw material transition for a bit longer. For instance, the steam released from waste incineration is used by other companies on the industrial estate. This ensures CO₂ reduction at these companies. There is also a line where sludge is processed. Green gas is first extracted there by the Water Boards and the remaining sludge, which is burned at EEW, provides heat that is also 100% green and used by other companies. ‘In addition, in May we will start capturing CO₂ on a small scale,’ says site director Wilfred de Jager. ‘By washing flue gases, as it is called, you bind the CO₂, after which it is stripped and you have extracted CO₂. You can then use this product to produce new useful chemical molecules.’

EEW is working with the University of Groningen and the Chemport Innovation Centre on this. ‘The idea is that other companies can use it, so that we can eventually realise green chemistry together.’ The government would prefer to put CO₂ underground, but De Jager is less enthusiastic about that than reusing it. ‘Only storing CO₂ I see as short-term thinking. We prefer to offer the CO₂ as a raw material, which means it can be reused and you no longer have to use fossil carbon sources.’

Major challenges

That the chemical industry faces major challenges is something Professor of Biochemistry Matthias Heinemann is convinced of. ‘We are on the eve of a raw materials transition. We need to start making our products differently, for example by recycling even more, but there are limits to this. Studies have shown that we can make products more sustainable by capturing carbon atoms, which normally go into the air. The technology is still in its infancy, but it offers enormous opportunities. How wonderful it would be if soon the world produces with CCU technology from the Netherlands.’

Heinemann is convinced that Eemshaven/Delfzijl is the ideal place to apply CCU technology. ‘There is space, we can use large amounts of green energy, which is needed to reuse CO₂ and Delfzijl is not dominated by big fossil players. That in itself is not a problem, because the transition will probably have to be done by innovative companies and there are numerous of them in Delfzijl.’

For now, CCU technology does not yet have any major applications, or in other words it cannot yet be exploited commercially. ‘And that’s a shame,’ Heinemann believes. ‘We in the Netherlands need to start thinking seriously about what our future earning potential should look like. CCU is one of the techniques with which we can build a lead in the market and give our chemical industry the opportunity to go green. This makes companies want to come to this region. This is where it happens, because we can become global leaders with green chemistry. That is what I am hoping for.’